diy injection molding 3d print

Full kits it include all the parts for the scanner. These two methods vary greatly by approach and will.

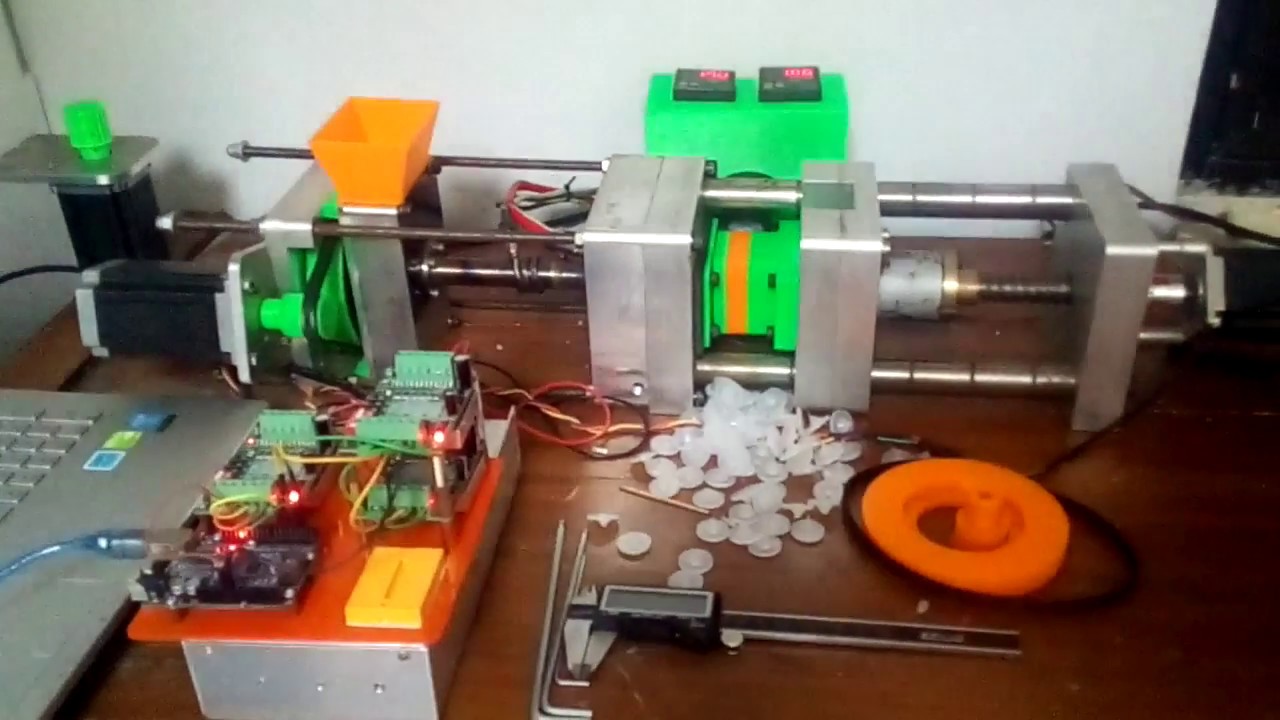

Diy Injection Molding With Double Pnuematic Plastic Injection Molding Mould Design Injection Moulding

3D printed injection molds can be used.

. To 3D print the mold its essential to pick a material that can withstand the temperature and pressure on the mold during the injection molding process. Ad Are you a molder responsible for developing and documenting a molding process. Get a Quote Today.

This time he shows off how to 3D print molds. This process is done by creating a mold of the item to be duplicated in this case the holder for a small cannon to be used in a museum display. Why no one thought of using a 3D.

Mounting holes can be modeled in the same pattern as a metal mold. The main differences between 3D printing vs Injection Molding are. 3D Print the Mold.

Get a Quote Today. 3D printed mold design is similar to metal molds. Injection molding has long been the optimal method to rapidly make plastic components in large quantities.

Totally open source 3D scanner for 3D printing free to get the software. Other reasons 3D printing might be chosen for mold production include the. Using your 3D printer to create molds is not only possible but easy.

Watch Out Hobbyist 3D Printing â Here Comes DIY Injection Molding. When it does and doesnt make sense to 3D-print molds. While there are certainly cases where 3D printing makes sense the reports of the death of injection molding have been greatly exaggerated.

From product development to industrial 3D manufacturing scaled to fit your business. If you have ever had to spend to make tooling for injection molding youll appreciate being able to make molds relatively. 3D printing in Loudoun County.

Injection molding machines are able to form very detailed plastic parts simply by squirting plastic into a mold. 3D printing molds for injection molding rather than creating them in the traditional multi-step manner saves time allowing manufacturers to get their products to market more. 3D printing is more expensive whereas injection.

First two 0124 holes are drilled through both blocks to hold guide pins that will ensure the mold halves. That mold is then injected. On average injection molded parts should have a wall thickness that.

Request a Quote Today. You will develop molding processes on a variety of machines. Check out our simple guide on how to make 3D printed molds yourself.

Request a Quote Today. Main Differences Between 3D Printing vs Injection Molding. Easy to assemble and use.

For low-run injection molding of 50 to 100 parts 3D printing can be a more cost-effective option. Ad Additive manufacturing and 3D printing support filament by Infinite. Published Mar 21 2020.

This means shorter cycle times resulting in more parts produced per hour and lower production cost. Ad 3D printing in Loudoun County surrounding Areas. 3D printers squirt plastic.

Injection molding red plastics parts not. A design process that plays to the strengths of 3D printing machining and low-volume injection molding can dramatically reduce development time to quickly bring a project. Learn mechanics of molding.

The proposed molds can be used to make a minimum of 10 and a maximum of 100 parts before having to be recycled and reprinted once again. 3D-printed molds are quick and relatively easy to produce. 3D printing in Loudoun County.

Ad From prototype to production get quality parts at consistently low prices. 3D printing injection molds slashes prototype lead time by 40. Ad 3D Printing Technologies.

By placing the molds in. However 3D printer manufacturer Type A Machines San. Ad Shapeways here to help build your product from concept to production.

Plastic injection molds cant be made in a. 3D printing meets injection molding. In injection mold and 3D print manufacturing there are significant process differences and these differences will dictate how one designs parts and components.

When you need quick parts jigs fixtures tooling and handling accessories. Flexible anti-static hoses for plastic pellets and high temp hoses for air and fumes. Learn how to create 3D printed injection molds for low-volume in-house injection molding to produce small functional parts in production plastics.

Ad 3D printing in Loudoun County surrounding Areas. Both processes play a role in. A 1500 hand-operated bench-model plastic injection machine funded via.

Caverna is designed for FFF printers available in both 175mm and 285mm filaments. The video on the Action Box channel on Youtube. There are two ways to use 3D printing for injection molding either for creating a prototype or to create the mold itself.

Two little blocks of 6061 aluminum make up the halves of the mold. Find out why 3D printed injection molds exist and how you can make one. And if overmolding or dual material injecting is desired.

And heres an application example of the Italian division of international consumer goods giant Unilever. Ad Get injection molding hoses for exhaust fumes air ventilation and plastic conveying. A couple of hobbyists in Canada have a solution a DIY injection molding machine that can fit on almost any desktop.

Your one-stop-shop for high quality 3D printed parts at an affordable price. MJF FDM FFF SLS.

Bestseller Books Online Build A Plastic Injection Molding Attachment For A Drill Press Vincent R Plastic Injection Molding Plastic Injection Plastic Moulding

Desktop Injection Support By 3d Printed Controlled By Arduino Uno Youtube Arduino Plastic Injection Plastic Injection Molding

Pin By Ahmad On 3d Printing Plastic Injection Moulding Machine Plastic Injection Molding Diy Molding

History Plastic Injection Molding Injection Machine Plastic Moulding

3d Printed Flexible Casting Mold 3d Printer Designs 3dprinting Design 3d Printing Projects

Diy Filament Extruder 3d Printing Diy 3d Printer Filament Diy

3d Printing For Molds And Dies Part 1 3dprint Com The Voice Of 3d Printing Additive Manufacturing Injection Moulding Process Plastic Moulding Injection Moulding

Model 150a Plastic Injection Machine Plastic Injection Diy Molding 3d Printing

Get The Screws Turning Part 3 Of 3 Exploring The Technology Of 3d Printed Injection Molds Goengineer 3d Printing Machine 3d Printing Diy Plastic Moulding

How To Use 3d Printing For Injection Molding Mold Making 3d Printing Plastic Moulding

Pin On Plastic Injection Molding

Spinning Snap Connection Mechanical Design 3d Printer Designs Plastic Design

See How Hasco 3d Prints Quick Change Injection Molds Stratasys Injection Moulding 3d Printing Machine 3d Printing Business

Revolutionizing The Injection Molding Process Ennomotive Injection Moulding Process 3d Printing Business 3d Printing Machine

3d Printing Impacts Production Mold Design Additive Manufacturing Prints Mould Design Plastic Moulding

Make Your Own Injection Molding Machine Make Diy Molding Plastic Injection Molding Epoxy Resin Crafts

Injection Mold Flash Google Search Injection Moulding Process Diy Molding Mould Design

3d Printed Mold For Injection Molding 3d Printer Designs 3d Printing 3d Printer